Softinery is a provider of custom process simulation software and services. Improve your product, decrease costs with the help of advanced simulation. Reach the goal with our help. Get free consultation about the problem you want to solve.

Superior Engineering Using Process Simulations

The demands on product quality and sustainable manufacturing are constantly increasing. Satisfying this demand is associated with a high amount of work and time due to the increasing complexity of manufacturing technology. This also means that the failure rate of new solutions is extremely high. Producers are looking for effective ways to shorten the time-to-market, obtain lower production costs and ensure the safety of the environment and people.

Fourth industrial revolution (Industry 4.0) has changed the way companies manufacture, improve and distribute their products. Manufacturers are integrating new technologies, cloud computing, artificial intelligence and machine learning into their production facilities. Softinery is a company that creates software for industry 4.0 and the research and development sector. We also conduct programming training for engineers.

What is Simulation?

Simulation is defined as “the imitation of the operation of a real-world process or system over time.” Simulations are ubiquitous in engineering and industrial operations. Imitating a real-world system allows experts to study it’s behaviour in a controlled, repeatable environment.

Why To Use Simulation In Production and Manufacturing?

Computer simulation is a tool that gives great opportunities when designing technological processes. It is also a key technology for developing planning models, optimizing decision making, as well as designing and operating complex and intelligent manufacturing systems. Through the use of simulation, organizations gain the ability to study the behavior of their production processes and systems before implementing them. Since setting up new production facilities, production lines and processes is often costly, applying process simulations to production can bring huge benefits.

Benefits of Process Simulations

- Identifying process bottlenecks and opportunities to increase efficiency

- Reducing costs by process optimization

- Validating the expected performance of new and existing production lines

- Improving process control by application of model-based control systems

Our Offer

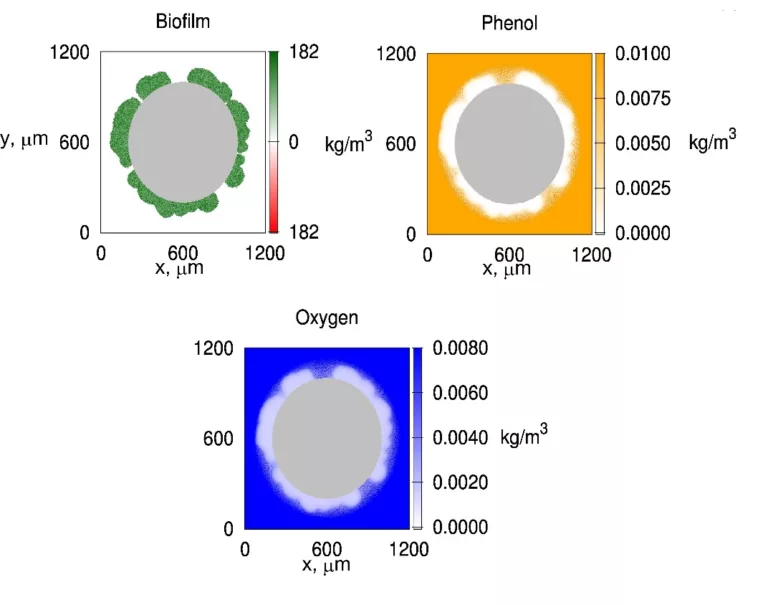

Softinery offers services related to chemical engineering processes, such us system analysis, process design and modelling, simulation, verification and parameters identification. We have unique commercial and academic experience in merging applied mathematics and science knowledge in projects related to chemical reaction engineering, combustion, process simulation software development, statistical and physical mathematical models. Our company offers services based on expertise in areas including:

- Optimization

- Machine learning

- Numerical methods

- Discrete mathematics

- Control and fault diagnosis

- Signal, audio and video processing

Try our online for chemical engineeringsimulation software

Our new web application is designed for modeling and simulation of various processes, such as chemical reactors and PID control systems. It is continuously developed to cover more problems related to chemical processes and unit operations, like steady-state and dynamic simulation, heat exchangers, distillation, thermodynamics and more. Our software is a unique process simulator available online without necessity for installation, useful for process engineers, chemical engineering students and early career researchers. Try it for free!

Need process simulation consultant? Contact us

We are here to help. Contact us by phone, email or via our social media channels.

You can find our scientific papers in: