Problem description

Bioreactors are devices that utilize microorganisms to produce valuable compounds or neutralize toxic substances. The design of these devices is based on mathematical models that describe the phenomena occurring inside the apparatus. Engineers use mathematical models in the optimization of industrial processes. They enable the determination of parameters that ensure maximum production efficiency.

Approach

Mathematical models can be categorized into several types based on their purpose. CFD (Computational Fluid Dynamics) models are used for a detailed description of fluid behavior and are typically applied to analyze design solutions for devices (e.g., the impact of agitator design on the formation of dead zones). Another group comprises models based on differential equations. This approach strikes a balance between the level of detail and practicality, making it a popular choice for addressing real-world problems. Based on this approach, we have developed models for continuous stirred-tank reactors (CSTRs) and tubular reactors.

Results

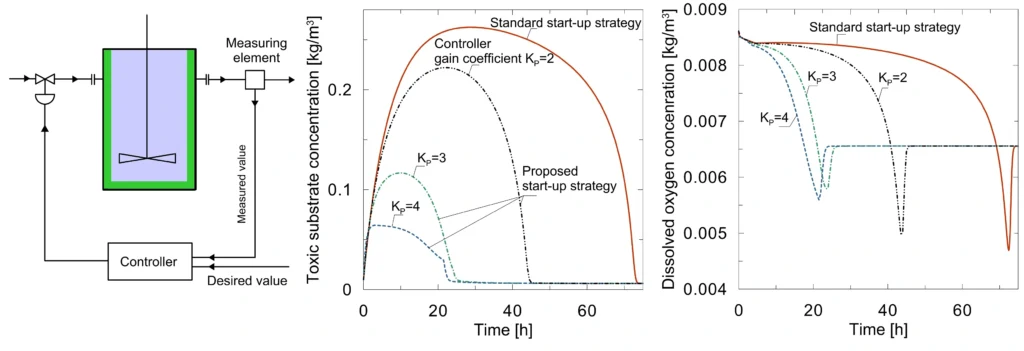

- We have optimized operation of bioreactors using the developed models. One of the solutions designed is a bioreactor startup method that reduces the duration of this phase several times compared to the standard approach.

- The simplified mathematical method we developed enables precise prediction of bioreactor dynamics without the need for advanced numerical methods, significantly streamlining the design and optimization process.

Tools

The project utilized Matlab, Python, and C++. We have used Matlab for simulations and model analysis, Python for process automation and visualization, and C++ for implementing key algorithms to ensure computational efficiency.