Plug-flow reactor model

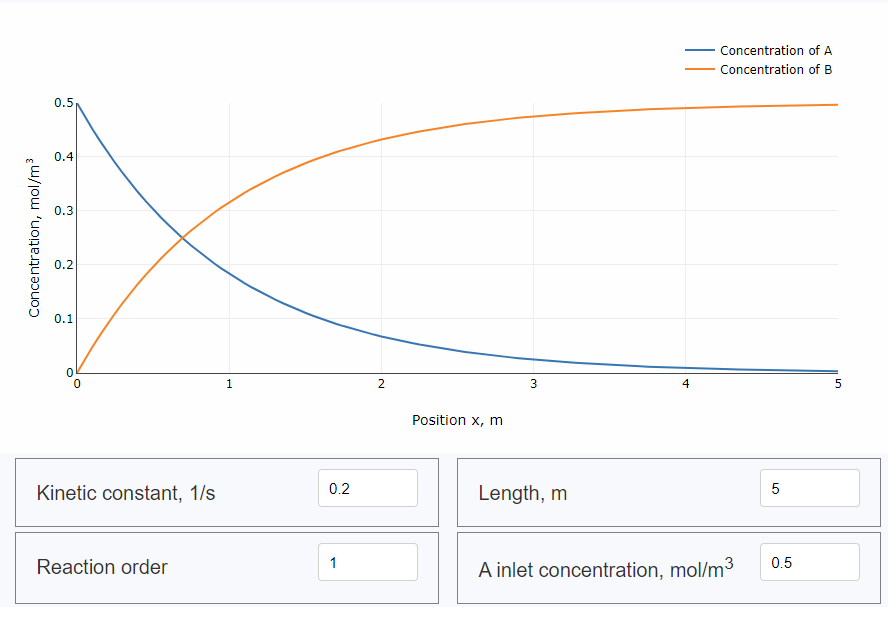

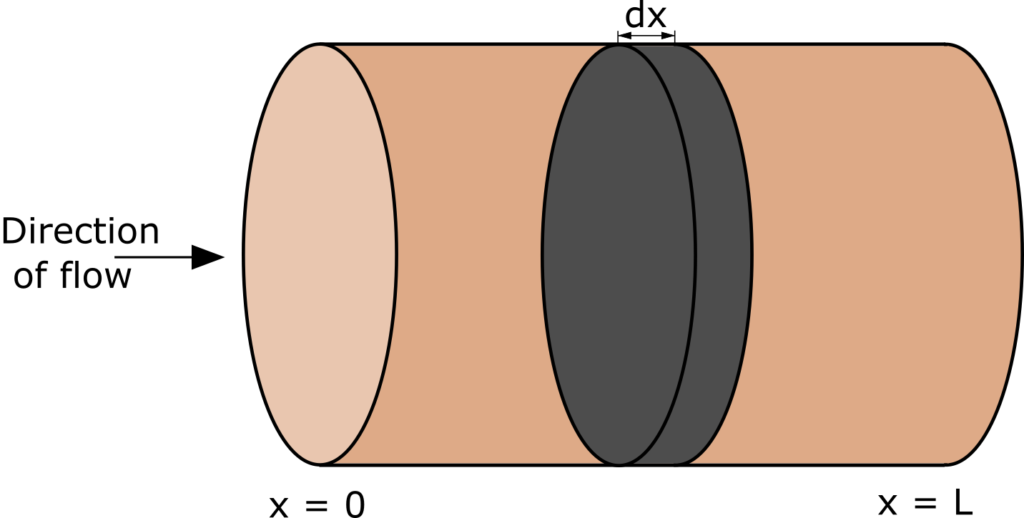

Plug-flow reactor (PFR, sometimes called piston-flow reactor or tubular reactor) is an idealized reactor in which all particles in a given cross-section have identical velocity and direction of motion. In PFR there is no mixing or back flow, so the fluid flows like a plug, from inlet to outlet (Figure below).

Plug flow reactor model is formulated based on mass balance and heat balance in a differential volume of a fluid (Fig. 1). If we assume that the process is isothermal (heat of reaction is negligible), then only mass balance is considered. We will assume steady state conditions, which mean that concentrations of reactant do not change over time. It is a typical way of operation of plug flow reactors.

The mathematical model of PFR can be written as follows (Levenspiel, 1998):

![]()

![]()

![]()

In the above equation Ci is reactant i concentration, u denotes fluid velocity, νi is the stoichiometric coefficient, r is the reaction rate and x is the position in the reactor. Caf is reactant A concentration at the reactor inlet (in the feed stream) and L is the reactor length.

The fluid velocity u is calculated based on the volumetric flow rate Fv (m3/s) and the cross-section area of the reactor S (m2):

![]()

In an ideal plug flow reactor, all the fluid particles have been inside the reactor for exactly the same amount of time (Fogler, 2010). We call this value a mean residence and calculate as

![]()

The residence time data is commonly used in chemical reactors engineering to make predictions of conversion and exit concentrations.

First-order irreversible reaction

Let’s consider simple decomposition reaction:

![]()

When the reaction is irreversible and first-order, then we have:

![]()

where k is a kinetic constant. In general, kinetic constant depends on temperature. Commonly an Arrhenius equation is used to describe this relationship. Here, we assume isothermal conditions, so will not use this dependency.

For first-order irreversible reaction, the model can be solved analytically. The solution is following:

![]()

Second-order irreversible reaction

As an example of a second-order irreversible reaction, let’s use the following one:

![]()

When the reaction is irreversible and second-order, then we have:

![]()

Simulation of plug flow reactor

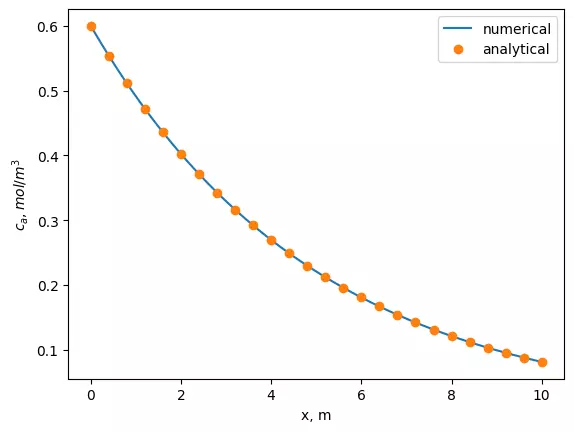

First-order reaction

First, let’s import necessary libraries: numpy for matrix operations, scipy for solving differential equations and matplotlib for making a chart.

import numpy as np

from scipy.integrate import odeint

import matplotlib.pyplot as pltNext, we will define reaction function. In this example we use first-order irreversible reaction.

def reaction(ca, k):

r = k * ca

return rThe function plug_flow describes the differential equation.

def plug_flow(ca, x, k, ni, u):

r = reaction(ca, k)

dcadx = ni * r / u

return dcadxSnippet below presents the definition of model parameters.

# kinetic constant

k = 0.1

# reactor length

L = 10

x = np.linspace(0, L, 101)

ca0 = 0.6

ni = -1

u = 0.5Next, we will use odeint function from scipy library to solve the differential equation.

sol = odeint(plug_flow, ca0, x, args=(k, ni, u))Finally, we will plot the results together with the analytical solution for the comparison.

plt.plot(x, sol)

plt.plot(x[::4], [ca0 * np.exp(-x*k/u) for x in x[::4]],'o')

plt.xlabel('x')

plt.ylabel('$C_{a}$')

plt.legend(['numerical', 'analytical'])

plt.plot

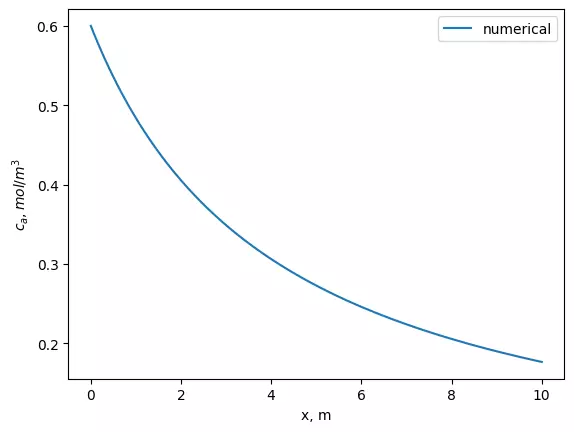

Second-order reaction

Obtaining the solution is very similar. We need to change the reaction function and coefficient ν. The final code looks as follows:

import numpy as np

from scipy.integrate import odeint

import matplotlib.pyplot as plt

def reaction(ca, k, n):

r = k * ca ** n

return r

def plug_flow(ca, x, k, ni, u, n):

r = reaction(ca, k, n)

dcadx = ni * r / u

return dcadx

# kinetic constant

k = 0.1

# reactor length

L = 10

x = np.linspace(0, L, 101)

# inlet A concentration

ca0 = 0.6

# reaction order

n = 2

# stoichiometric coefficient

ni = -2

# fluid velocity

u = 0.5

sol = odeint(plug_flow, ca0, x, args=(k, ni, u, n))

plt.plot(x, sol)

plt.xlabel('x, m')

plt.ylabel('$c_a, mol/m^3$')

plt.legend(['numerical'])

plt.plot

References

Try online plug-flow reactor simulator

Read related content

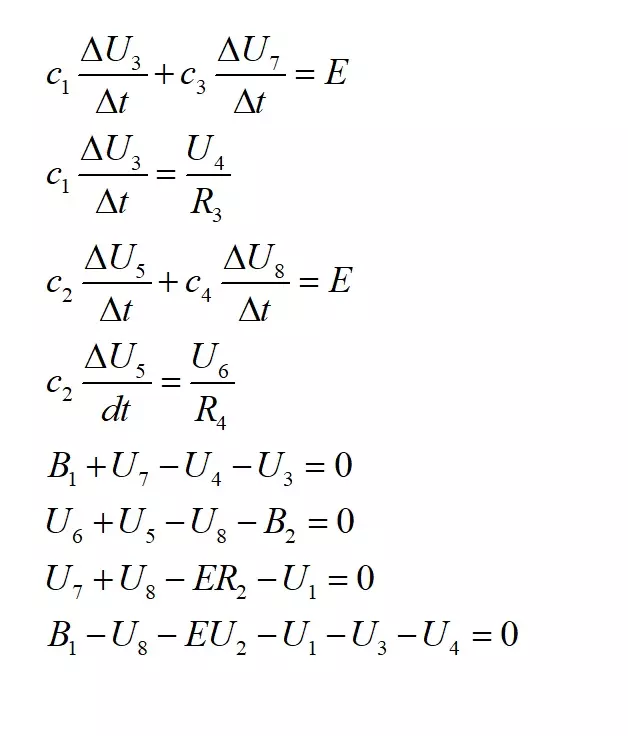

How to solve system of DAEs in Python